High concentration of solids

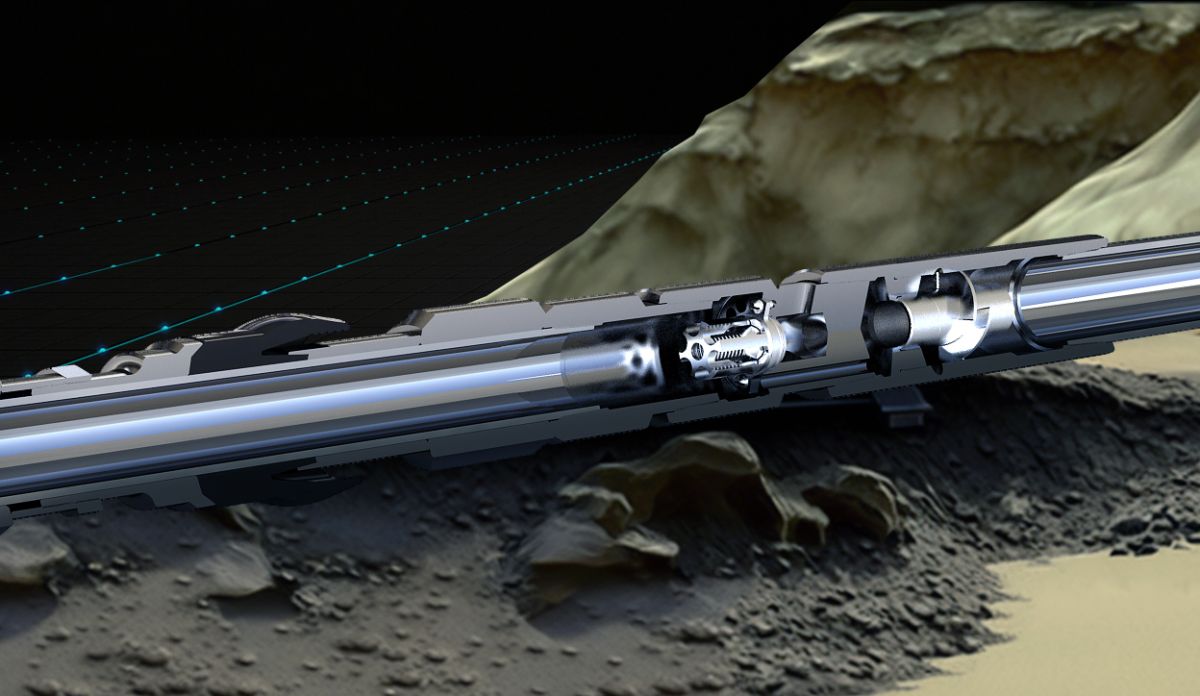

A large amount of solids in the extracted oil complicates the operation of wells, increases the wear of equipment, complicates the maintenance of wells, while increasing operating costs

In such conditions, pump parts wear out very quickly, and the reliability of the submersible motor's protector decreases.

The impurities contained in the pumped liquid are different in qualitative and quantitative composition: these may be the products of reservoir or cement sheath destruction, or particles of various compositions brought from the surface.

However, their effect on all pumps is identical: they clog the pump filters, first reducing and then completely stopping the flow of liquid into the pump, or act as an abrasive, accelerating the process of wear of pump elements or jamming them.

Deposits of the sulfide-sand type are the most dangerous for ESPs, since, compared with deposits of another type, they cause intense abrasive wear of rotating parts and, as a result, premature failure of the unit, and in some cases, falling of the unit to the bottom.

Do you also have a well with

a high solids content?

Learn more about how to deal with this

Do you want to know more?

Contact us to learn more about ALMAZ Oifield Service equipment and solutions, the possibilities of increasing the service life of ESPs at your current project