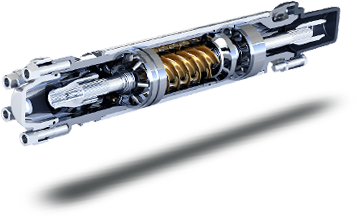

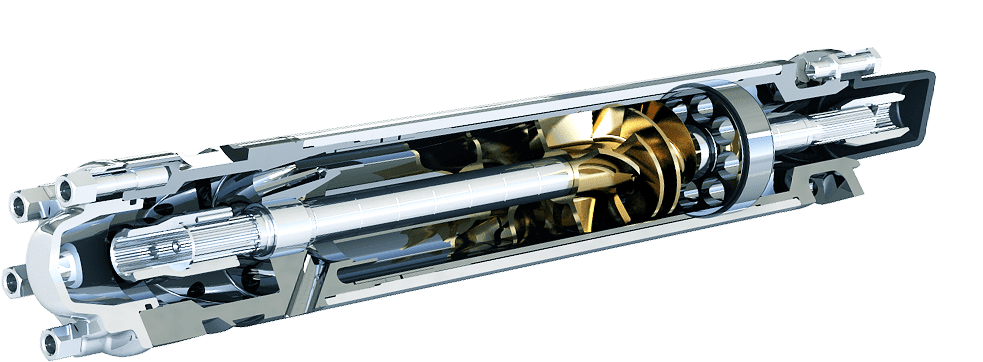

Handler pump module

Gas separators, Gas stabilizers, Gas separators/handlers, Handlers

For the operation of wells with free gas in the produced well products, we will apply an effective solution for the selection of pre-connected pump modules.

Watch video

-

Equipment composition

Equipment compositionGas separators

Maximum allowable free gas content at the inlet:

- 55% for the basic design

- 68% for the vortex design -

Equipment composition

Equipment compositionGas stabilizers

Small-sized Maximum allowable free gas content at the inlet:

- 55% -

Equipment composition

Equipment compositionGas separators/handlers

Maximum allowable free gas content at the inlet:

- 65% for the basic design

- 75% for the vortex design

Purpose

The pump module is designed for joint use with pumps

in wells with a high gas content and can be installed

before the pump inlet. It performs, depending on the type, the function of the inlet

module with simultaneous separation of the gas-liquid mixture into two fractions

or separation and (or) dispersion of the gas-liquid mixture.

Depending on the customer's request, the pump module can be

upgraded and used to attach the motor housing.

Decoding of the series

series 31 TU 3665-015-27385465-2017

The first digit is a design designation that takes into account the categories of complicating factors, corrosion resistance and wear resistance:

1 – equipment in standard design, designed for use in wells with negligible influence of all complicating factors

2 – equipment in corrosion-resistant design for use in wells with increased corrosion aggressiveness of reservoir fluid with negligible gas-oil ratio and temperature

3 – equipment in wear-resistant design for use in wells with increased content of solids in reservoir fluid, moderate ga-oil ratio and temperature

4 – equipment in wear-resistant and corrosion-resistant design for use in wells with increased corrosion aggressiveness of reservoir fluid, increased content of abrasive components, moderate gas-oil ratio and temperature

5 - equipment in corrosion-resistant design with increased abrasive resistance for use in wells with increased corrosion aggressiveness of reservoir fluid, increased content of abrasive components of over 500 mg/l, high gas-oil ratio and temperature

6 – equipment in a particularly wear-resistant design for use in wells with a content of solids in the reservoir fluid of over 500 mg/l, high gas-oil ratio and temperature

The second digit is the code indicating the design (in-house designation) of the pump module:

0 – previously installed code of pump modules (for example, GSD5.1-250);

1 – code of the gas separator pump module (MNGRI(K));

2 – code of the handler pump module (MNDRI(K)), or the gas separator/handler pump module (MNGDRI(K));

3 – code of the pump module the vortex type stage (MNVGRI(K), MNVGDRI (K));

4 – the code of the gas stabilizer pump module (MNSGRI(K));

5 and further – alternative versions of the pump module codes.