ESP

Electric

submersible pumps

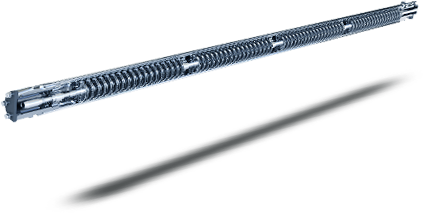

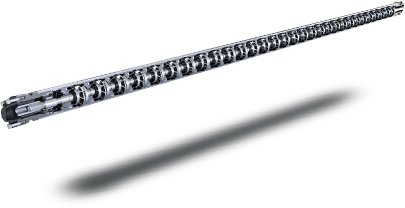

Electric submersible pumps are used as part of electric submersible pump units for movement of reservoir fluid under pressure.

The following pumps can be supplied:

- Sizes: 2A, 3, 4A, 5, 5A, 6, 6.B; 8

- Purpose: conventional, booster pumps and pumps for reservoir pressure maintenance systems (reversible)

- Capacity: from 15 m3/day to 2,500 m3/day

- Head: up to 3,800 m

- Section length: 2; 3; 3,5; 4; 4,5; 5 m; 5.5; 6 m

- Design: supported or unsupported (support in the protector)

- Stage design: single-support, single-support with an elongated hub or double-support, open type.

- Assembly type: assembly with floating stages, batch-type or compression-type

- Reservoir fluid temperature: conventional 110 °C, heat-resistant 135 °C,

or extra heat-resistant temperature version 170 °C - Wear resistance (material of stages): they can be equipped with stages

(working bodies) made of cast iron, Ni-resist type I, Ni-resist type IV,

powder pseudo-alloys, high-alloy powder alloy,

stainless steels and other alternative materials - Corrosion resistance: conventional or corrosion-resistant (K) design

- Type of spline shaft design:

straight spline or involute spline connection - Connection: with six-, eight-

and ten-point design

(thread pitch may vary from the customer's request) - Connection type:

housing-flange or flange-flange

Description of identifiers

The structure of the pump identifier in orders, correspondence and in other documentation

prepared by Almaz Oilfield Service LLC:

series 3208 TU 3665-015-27385465-2017

- (Л)

- working rotation of the shaft is left (only at the request of the customer; except for pumps of reversed type)

- no letter

- working rotation of the shaft is right (serial)

Equipment order

Do you need technology-savvy equipment? If you need to develop and manufacture process equipment «Almaz Oilfield Service» can review your request and implement the project