Protectors

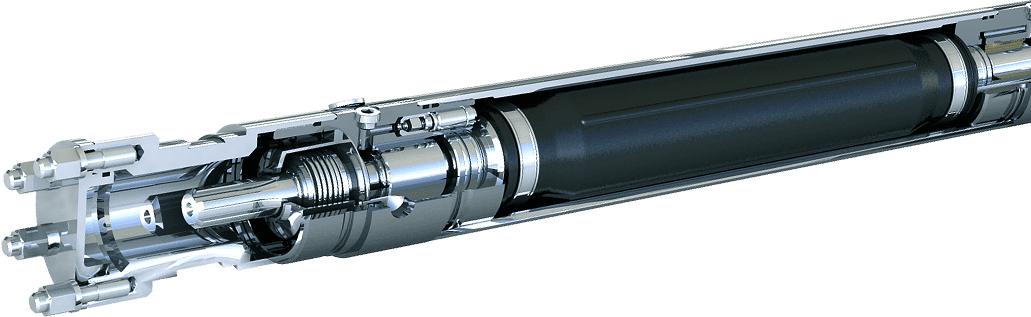

A protector is designed to protect the internal cavity of the electric motor from the ingress of reservoir fluid, to compensate for changes in oil volume, to transfer torque from the motor shaft to the input module shaft.

Individual protector designs can also transmit torque to the ESP shaft (double-sided unit).

Protectors can be either of conventional (PA) or modular (MPA) design.

They may differ in the number of diaphragms, labyrinths, bearings, end seals.

They can be of conventional purpose and of increased reliability (up to 4 diaphragms and three end seals).

Purpose

PA type protectors are designed to transfer torque from the electric motor to the pump, protect submersible oil-filled electric motors from penetration of reservoir fluid into their internal cavity, compensate for oil leakage and thermal changes in its volume during operation of the electric motor. PA type protectors are designed for submersible electric motors with a housing diameter of 81, 95, 100, 103, 117 and 130 mm, and other motors with the corresponding overall dimensions, connection dimensions and technical characteristics, used as a drive for centrifugal pumps of unsupported design for oil production. It is allowed to use them with pumps having axial shaft supports. PA type protectors can also be of modular design (MPA), and of a version designed for double-sided motors (2PA, 2MPA), for the motor of the unit injecting liquid into the below-packer space (5PA), for telemetry systems, if differential pressure compensation is necessary (TPA).

The following protectors can be supplied:

- Sizes – 69, 81, 86, 90, 92, 103, 114

- Temperature resistance – basic, heat-resistant (T) or extra heat-resistant (TT) temperature versions

- Corrosion resistance: conventional or corrosion-resistant design The corrosion-resistant version

can be made entirely of stainless steel or with a Monel-type coating - Design – conventional or for double-sided units (installed from the bottom of the motor)

- Direction of the shaft operating rotation – right (clockwise) or left (counterclockwise)

- Type of spline shaft design straight spline or involute spline connection

- Transmitted shaft power – T9...T14 yield strength groups

- Material of the shaft – stainless steel or alloy of K-monel type

- Connection with ESP motor: with six-, eight- and ten-point design of

studs (thread pitch may vary from the customer's request) - Connection with inlet (pump) module – with six-,

eight- and ten-point

design of studs (thread pitch may vary from the customer's request). - Design of valves – valve and valveless (B) type

- Design of diaphragm – with diaphragms, – without a diaphragm

- Design of labyrinths – with labyrinths, – without labyrinths

- At the customer's request, an

inlet module can be integrated into the protector head

Description of identifiers

The following structure of the protector identifier is established:

- М

- Modular

- Т

- to equip telemetry systems, if necessary, to compensate for pressure drops

- 2

- bottom protector for double-sided installation

- 5

- to equip units injecting liquid into the below-packer space

Х – design:

Design peculiarities of MPA-type protectors, basic versions:

MPA-92DL – similar to PA-92DL. It is distinguished by shortened diaphragm and hydraulic seal sections.

MPA-92D2L – similar to the MPA-92DL. It is distinguished by two shortened diaphragms, which increase the compensating ability.

MPA-92D2L2 – similar to MPA-92D2L. It is distinguished by two hydraulic seal shortened sections that provide more reliable protection of the motor from the penetration of reservoir fluid.

MPA-92VD2L2 – similar to MPA-92D2L2. It is distinguished by a head with a receiver.

MPA-92D2L2B – similar to MPA-92D2L2. It is distinguished by the absence of check valves.

Excess oil is discharged through the diaphragm valve assembly.

MPA-92L2L2 – it has two end seals and two double shortened hydraulic seal (labyrinth) sections. It has no check valves. Excess oil during its thermal expansion is discharged through the tube of the upper labyrinth.

MPA-69D2L2 – similar to MPA-92D2L2. It has a reduced diameter. It has a hydrodynamic axial thrust bearing capable of receiving a load of 360 kg. It is designed to equip a size 81 motor with an additional module.

MPA-69D2D2 – similar to MPA-69D2L2. It is distinguished by two double, shortened diaphragm sections separated by an end seal.

MPA-69D2L2M – similar to MPA-69D2L2. It differs by the increased diameter of the base flange. It is designed for a size 81 motor.

MPA-69D2D2M – similar to MPA-69D2D2. It differs by the increased diameter of the base flange. It is designed for a size 81 motor.

MPA-81DD – has two diaphragm sections separated by an end seal. It is designed for a size 81 motor.

The MPA-86D2L2u – similar to MPA-92D2L2. It has a reduced diameter. It has a hydrodynamic axial thrust bearing capable of receiving a load of 650 kg. It is designed for a size 95 motor.

MPA-90D2L2 – similar to MPA-92D2L2. It has a reduced outer diameter.

It is designed for a size 100 motor.

MPA-92D2D2L – it has two double, shortened diaphragm sections separated by an end seal and one shortened labyrinth section.

MPA-103D2L2 – similar to MPA-92D2L2. It is distinguished by a hydrodynamic axial bearing of increased size, capable of receiving an axial load of up to 950 kg.

MPA-103D2D2L – similar to MPA-92D2D2L. It is distinguished by a hydrodynamic axial thrust bearing of increased size.

PA-103DLu – similar to PA-92DL. It is distinguished by an increased shaft diameter, to transmit more torque, and a hydrodynamic thrust bearing receiving a load of up to 950 kg.

MPA-103D2L2u – similar to MPA-103D2L2. It is characterized by an increased shaft diameter.

MPA-103D2D2Lu – similar to MPA-103D2D2L. It is characterized by an increased shaft diameter.

MPA-114D2L2 – similar to MPA-103D2L2. It is distinguished by a hydrodynamic axial bearing of increased size, capable of receiving an axial load of up to 1,200 kg.

PA-114DL – similar to PA-103DLu. It is distinguished by a hydrodynamic axial bearing of increased size, capable of receiving an axial load of up to 1,200 kg.

PA-114DL – similar to PA-114DL. It is distinguished by an increased shaft diameter to transmit more torque.

Design peculiarities of the protector type 2PA, 2MPA, basic design:

2MPA-92 – it has one end seal and a shaft transmitting torque from the motor of the pump booster section in the double-sided unit. The axial thrust bearing of the protector is not designed to receive additional loads.

Design peculiarities of PA type protectors, basic versions:

PA-92DLuM5 – it has two end seals, a diaphragm and a hydraulic seal (labyrinth) section. The diaphragm and rubber parts of the protector are made of heat-resistant rubber (up to +250 °C, depending on the design). Excess oil during its thermal expansion is discharged through two check valves installed in series.

5PA-92DL73 – similar to PA-92DL. It is distinguished by the absence of a shaft and end seals. It provides compensation for pressure drops and discharge of excess oil during its thermal expansion. It can be equipped with a head with tubing thread as per GOST 633.

TPA-92D73 – similar to 5PA-92DL. It is distinguished by the availability of the diaphragm cavity only.

TPA-86D60 – similar to TPA-92D. It is characterized by a reduced size.

List of protector designs

| Protector type | Shaft diameter, mm. | Motor size, mm. | Pump size | Note |

|---|---|---|---|---|

| МПА-69Д2Л2 | 14 | 81 | 2А | With an additional module |

| МПА-69Д2Д2 | ||||

| МПА-69Д2Л2М | ||||

| МПА-69Д2Д2М | ||||

| МПА-81ДД | 20 | 81 | 3 | |

| МПА-86Д2Л2у | 25 | 95 | 4,4А | |

| МПА-90Д2Л2 | 100 | |||

| ПА-92ДЛуМ5 | 103,117 | 5,5А | ||

| МПА-92ДЛ | ||||

| МПА-92Д2Л | ||||

| МПА-92Д2Л2 | ||||

| МПА-92ВД2Л2 | ||||

| МПА-92Д2Л2Б | ||||

| МПА-92Д2Л2Е | With imported gas separator | |||

| МПА-92Д2Д2Л | ||||

| 2МПА-92 | ||||

| 5ПА-92ДЛ73 | - | - | Head with coupling thread 73 GOST 633-80 | |

| 5ПА-92ДЛ | - | - | ||

| ТПА-92Д73 | - | - | - | Head with coupling thread 73 ГОСТ 633-80 |

| ТПА-92Д | - | - | - | |

| ТПА-86Д60 | - | - | - | Head with coupling thread 60 ГОСТ 633-80 |

| ТПА-86Д | - | - | - | |

| МД-69 | 20 | 81 | 2А | |

| МД-92 | 25 | 117 | 5.5А | |

| ПА-103ДЛу | 28 | 5А | ||

| МПА-103Д2Л2 | 25 | 103,117 | 5,5А | |

| МПА-103Д2Л2у | 28 | 117 | 5А | |

| МПА-103Д2Д2Л | 25 | 103,117 | 5,5А |

List of protector designs

| Protector parameters | Comes with an ESP motor: Power, kW | Maximum permissible axial load on the shaft, kg | Power consumption without axial loading, kW, max | Power consumption with axial load, kW, max | Shaft rotation speed, rpm | Number of end seals | Volume of oil to be filled, l | Weight, kg | |

|---|---|---|---|---|---|---|---|---|---|

| МПА-69Д2Л2 | До 65 | 360 | 0,4 | 1 | 3000 | 2 | 3,3 | 34,3 | |

| МПА-69Д2Л2М | До 65 | 360 | 0,4 | 1 | 2 | 3,3 | 34,8 | ||

| МПА-81ДД | До 120 | 560 | 0,5 | 1,1 | 2 | 4,5 | 39,5 | ||

| МПА-86Д2Л2у | До 150 | 650 | 0,8 | 1,2 | 2 | 6 | 72,5 | ||

| МПА-86Д2Л2у | До 36 | 750 | 0,6 | 1 | 2 | 7,3 | 77 | ||

| МПА-90Д2Л2 | До 210 | 750 | 1 | 1,4 | 2 | 7,3 | 77 | ||

| ПА-92ДЛуМ5 | До 360 | 750 | 0,6 | 1 | 2 | 7,4 | 68 | ||

| МПА-92ДЛ | До 36 | 750 | 0,6 | 1 | 2 | 4 | 53 | ||

| МПА-92Д2Л | До 90 | 750 | 0,9 | 1,3 | 2 | 5,6 | 68 | ||

| МПА-92Д2Л2 | 100-125 | 750 | 1 | 1,4 | 2 | 7,4 | 82,7 | ||

| МПА-92ВД2Л2 | 100-125 | 750 | 1 | 1,4 | 2 | 7,4 | 82,6 | ||

| МПА-92Д2Л2Б | 100-125 | 750 | 1 | 1,4 | 2 | 7,4 | 82,7 | ||

| МПА-92Д2Л2Е | 100-125 | 750 | 1 | 1,4 | 2 | 7,4 | 82,7 | ||

| МПА-92Д2Д2Л | До 360 | 750 | 1,1 | 1,5 | 3 | 8,6 | 99,7 | ||

| 2ПА-92 | До 360 | 100 | 0,4 | 1 | 1 | 6,9 | 35 | ||

| МД-69 | До 65 | - | 0,4 | - | - | 2,1 | 18,3 | ||

| МД-92 | До 360 | - | 0,4 | - | - | 4,6 | 34 | ||

| ПА-103ДЛу | 200-360 | 950 | 1 | 1,6 | 2 | 10 | 68 | ||

| МПА-103Д2Л2 | 140-360 | 950 | 1 | 1,6 | 2 | 7,5 | 86 | ||

| МПА-103Д2Л2у | 220-360 | 950 | 1,2 | 1,8 | 2 | 10,1 | 97 | ||

| МПА-103Д2Д2Л | До 360 | 950 | 1,3 | 1,9 | 3 | 8,7 | 102,8 | ||

| МПА-103Д2Д2Лу | 220-360 | 950 | 1,4 | 2 | 3 | 11,9 | 116,6 | ||

| ПА-114ДЛ | До 480 | 1200 | 1,2 | 2,2 | 2 | 10,2 | 85,2 | ||

| ПА-114ДЛМ | 220-360 | 950 | 1,2 | 1,8 | 2 | 10,1 | 79,6 | ||

| ПА-114ДЛМ5 | До 480 | 1200 | 1,2 | 2,2 | 2 | 10,2 | 84 | ||

| ПА-114ДЛу | До 640 | 1200 | 1,4 | 2,4 | 2 | 11,5 | 102,4 | ||

| МПА-114Д2Л2 | До 480 | 1200 | 1,2 | 2,2 | 2 | 10,2 | 103,6 | ||

| МПА-114Д2Л2М | 220-360 | 950 | 1,2 | 1,8 | 2 | 10,2 | 98,1 | ||

| 5ПА-92ДЛ73 | До 360 | - | - | - | - | - | 7,7 | 46,4 | |

| 5ПА-92ДЛ | До 360 | 7,7 | 47,4 | ||||||

| ТПА-86Д60 | - | 1,5 | 18 | ||||||

| ТПА-86Д | 1,5 | 20 | |||||||

| ТПА-92Д73 | 1,9 | 21,5 | |||||||

| ТПА-92Д | 1,9 | 22,5 | |||||||