КИФБП-230 (250)

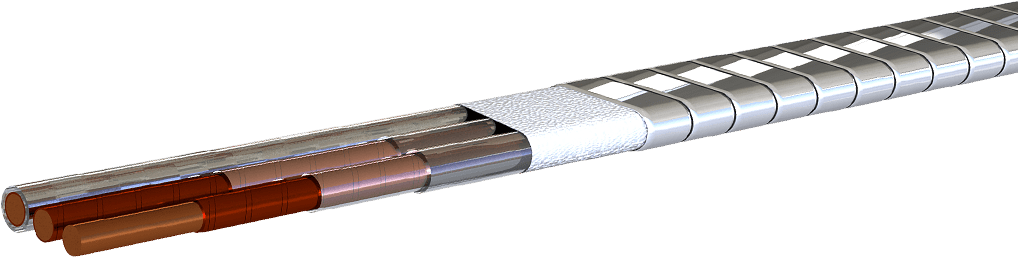

Flat cable for electric pump units with copper cores, with insulation of the first layer made of polyimide film, with insulation of the second layer made of extruded fluoropolymer, additional two-layer insulation made of extruded fluoropolymer, bedding made of non-woven fabric or glass tape, armored steel or stainless galvanized tape.

Heat resistance: 230 (250)°C

Manufactured sections: 7, 8, 10, 13, 16, 21,13; 35 mm 2

Design peculiarities: Minimum weight and dimensions

It retains flexibility at a temperature of minus 60 °C

Permissible voltage – 5,000 V

Design

1. Conductive core – copper single-wire;

2. Insulation of the first layer – polyimide film;

3. Insulation of the second layer – extruded fluoropolymer;

4. Insulation of the third layer – extruded fluoropolymer;

5. Bedding – tape made of non-woven fabric or glass tape;

6. Armor – galvanized steel or stainless steel tape.

It is designed for AC voltage with a frequency of 30 to 200 Hz for cables with a nominal cross section of 3x7 mm2, 3x8 mm2, 3x10 mm2, 3x13.3 mm2, 3x16 mm2, 3x21.15 mm2, 3x25 mm2, 3x35 mm2, rated voltage of 5,000V, operated in certain borehole conditions.

The cables are manufactured for the needs of the national economy and for export. Type of climatic version – UHL (NF), placement category 1 and 5 according to GOST 15150 and in reservoir fluid.

Decoding of the identifier for the submersible heat-resistant cable

The structure of the identifier for the submersible heat-resistant cable with fluoroplastic insulation, manufactured by Almaz Oilfield Service LLC, in orders, correspondence and in other documentation :

- К

- Cable with copper cores

Description of the cable line identifier

The structure of the cable line identifier in orders,

correspondence and in other documentation prepared by Almaz Oilfield Service LLC:

- КЛ

- cable line manufactured by Almaz Oilfield Service LLC

Characteristics of downhole conditions

| Parameters of downhole conditions | Standard design | Corrosion-resistant design |

|---|---|---|

| Produced water pH factor | 5,0-8,5* | 3,0-9,5* |

| Maximum mass concentration of solid particles, % | 0,1 (1,0) | 0,1 (1,0) |

| Microhardness of particles (on the Mohs scale), max | 7 | 7 |

| Maximum mass concentration of solid particles, % | 100 | 100 |

| GOR of reservoir fluid, max, m3/t | not limited | not limited |

| Hydrostatic pressure, max, MPa (kgf/cm2) | 40 (400) | 40 (400) |

| Maximum concentration H2S, % | 0,001 (0,01) | 0,125 (1,25) |

| Maximum concentration СО2 , % (г/л) | - | 0,115 (1,15) |

| Maximum concentration Сl -,% (г/л) | - | 7,5 (75) |

| Maximum concentration НСО3 % (г/л) | - | 0,1(1) |

| Maximum concentration SO42-, % (г/л) | - | 0,2 (2) |

| Maximum concentration Са 2+ % (г/л) | - | 0,9 (9) |

| Maximum concentration (Na+ +K +)% (г/л) | - | 7,0 (70) |

| Maximum temperature of well fluid or gas-air medium (applies to ESP), max, °C | 180 | 180 |

Design weight of 1 km of cable, kg

| Cable type | Number and nominal cross-section of cores | |||||||

|---|---|---|---|---|---|---|---|---|

| 3х7 | 3х8 | 3х10 | 3х13,3 | 3х16 | 3x21,15 | 3х25 | 3х35 | |

| КИФБП-230 КИФБП-250 | 700 | 770 | 875 | 955 | 1130 | 1320 | 1470 | 1630 |

Nominal cross-section and diameter of the core

| Nominal diameter of conductive core, mm | Nominal cross-section of conductive core, mm2 |

|---|---|

| 3,00±0,02 | 7 |

| 3,20±0,02 | 8 |

| 3,57±0,03 | 10 |

| 4,10±0,03 | 13,3 |

| 4,50±0,04 | 16 |

| 5,15±0,05 | 21,15 |

| 5,65±0,05 | 25 |

| 6,68±0,05 | 35 |

Overall dimensions

| Cable grade | Number and nominal cross-section of cores, 2 mm | Maximum outer dimensions of the cable, mm | Nominal construction length, m |

|---|---|---|---|

| КИФБП (К) - 230 КИФБП (К) - 250 | 3х7 | 22,3х10,1 | 2500 |

| 3х8 | 23х10,5 | 2500 | |

| 3х10 | 24,5х11,5 | 2500 | |

| 3х13,3 | 27,5х12 | 2300 | |

| 3х16 | 29,5х12,5 | 2000 | |

| 3х21,15 | 31х13 | 2000 | |

| 3х25 | 33х13,5 | 1800 | |

| 3х35 | 33,5х14 | 1500 |