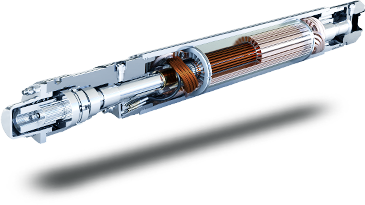

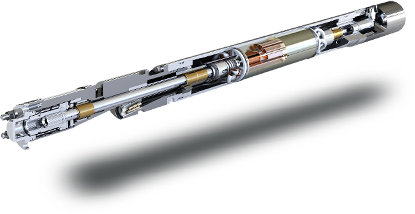

ESP motors

Almaz Oilfield Service manufactures several types of ESP motors:

asynchronous submersible three-phase oil-filled motors of PED-Ya and (N)PED-Ya (high voltage) series, oil-filled AC motors with permanent magnets in the rotor of VED-Ya series.

Watch video

Submersible motors manufactured by Almaz Oilfield Service

The motors can be supplied as a drive as part of units for oil production, for liquid injection (a mixture of iodine-bromine service water) into the below-packer space to raise (maintain) the pressure of the reservoir fluid (reservoir pressure maintenance systems), as part of double-sided units.

The following motors can be supplied:

- Sizes – 81,100, 103, 117, 130.

- Rated power (depending on the

design type: PED-Ya, (N)PED-Ya, RPPED-Ya, VED-Ya):

· size 81 up to 180 kW;

· size 100 up to 210 kW;

· size 103 up to 210 kW;

· size 117 up to 360 kW;

· size 130 up to 500 kW. - Temperature resistance – basic, heat-resistant (T) or extra heat-resistant (TT) temperature versions;

- Corrosion resistance – basic or corrosion-resistant (K) versions. The corrosion-resistant version can be made entirely of stainless steel or with a Monel-type coating;

- Direction of the shaft operating rotation – right (clockwise) or left (counterclockwise);

- Type of spline shaft design straight spline or involute spline connection;

- Connection with protector – with six-, eight- and ten-point design of studs (thread pitch may vary from the customer's request).

The following

design and process solutions are used in the motors manufactured by Almaz Group:

- Radial bearings with locking device against rotation in the stator;

- The stator lamination sheets are made with a closed groove and guide

elements to prevent them from turning relative to one another; - There is a keyway position mark on the stator housing – to indicate that there is no rotation of the stator lamination sheets in the housing;

- A fluoroplastic tube is used for groove insulation;

- Impregnation is carried out by vacuum method with Elplast-220 compound or

VS-346/A varnish; - The rotor packages are tested under load before being installed in the ESP motor;

- The output ends are heat-resistant

All motors have connection sizes standardized with domestic manufacturers. The manufactured motors have high maintainability, including at any service bases servicing the electric submersible units. In case of such a request, it is possible to manufacture them with adaptation to imported units.